Our Products

PVC-U pipe for water supply

Product introduce

PVC-U water supply pipe,as a developed and mature water supply pipe,has the advantages of acid

resistance,alkali resistance,corrosion resistance,pressure resistance,high strength,light weight,low price,low fluid resistance,no secondary pollution,sanitary requirements,convenient construction and operation.The pvc-u environmental protection water pipe produced by our factory can replace the traditional water supply pipe and

prevent secondary pollution,so that people can drink clean and healthy water.PVC-U pipe after strict testing shows that the product meets the requirements of various health standards,is a truly healthy,environmental protection of new products.

Product Feature:

- 1.Light weight,convenient handling,loading and unloading

Pvc-u pipe material is very light,the proportion is only 1/5 of the iron pipe,handling,loading and unloading, construction is convenient,can save construction costs.

- 2.Corrosion resistance,excellent drug properties

Pvc-u pipe has excellent acid,alkali and corrosion resistance,especially suitable for chemical industry, wastewater drainage,sanitary sewer and other aspects.

- 3.Low fluid resistance

The wall surface of pvc-u pipe is smooth,with litle resistance to fluid,and its roughness coefficient is only 0.009,lower than that of other pipes.In the case of the same diameter,the flow rate is large and there is no scale attached.

- 4.High mechanical strength

Pvc-u pipe has high water pressure resistance,external pressure resistance and impact resistance,which is suitable for supporting projects under various conditions.

- 5.Good electrical insulation

Pvc-u pipe has excellent electrical insulation performance,suitable for wire,cable protection sleeve,can be widely used in telecommunications,power and construction of the wire piping.

- 6.Does not affect water quality

Pvc-u pipe and fittings dissolution test results confirmed that it does not affect the water quality,for the current tap water supporting the best pipe.

- 7.Good water tightness

The combination of pvc-u pipe has a good water tightness,no matter whether it adopts loop socket or TS joint at the socket.

- 8.Easy construction

Pvc-u pipe construction is fast and convenient,and the construction cost is low.

Product Application:

Tap water engineering,electrical engineering,construction engineering,sewer engineering,electric wire engineering,drilling engineering,brine engineering,natural gas engineering,chemical factory,paper

factory,electroplating factory,agricultural field mine aquaculture industry,highway engineering,golf course engineering,fishery use plastic raft brewing fermentation factory etc

Specification:

Nominal Diameter (mm) | Wall Thickness(mm) | |||||

SDR26 | SDR21 | SDR17 | SDR13.6 | SDR11 | SDR9 | |

PN6 | PN8 | PN10 | PN12.5 | PN16 | PN20 | |

20 | 一 | 一 |

| 一 | – | 2 |

25 | 一 | 一 | 一 | 一 | 2 | 2.3 |

32 | – | – | – | 2 | 2.4 | 2.9 |

40 | 一 | 一 | 2 | 2.4 | 3 | 3.7 |

50 | 一 | 2 | 2.4 | 3 | 3 | 4.6 |

63 | 2 | 2.5 | 3 | 3.8 | 4.7 | 5.8 |

75 | 2.3 | 2.9 | 3.6 | 4.5 | 5.6 | 6.9 |

90 | 2.8 | 3.5 | 4.3 | 5.4 | 6.7 | 8.2 |

110 | 2.7 | 3.4 | 4.2 | 5.3 | 6.6 | 8.1 |

125 | 3.1 | 3.9 | 4.8 | 6 | 7.4 | 9.2 |

140 | 3.5 | 4.3 | 5.4 | 6.7 | 8.3 | 10.3 |

160 | 4 | 4.9 | 6.2 | 7.7 | 9.5 | 11.8 |

180 | 4.4 | 5.5 | 6.9 | 8.6 | 10.7 | 13.3 |

200 | 4.9 | 6.2 | 7.7 | 9.6 | 11.9 | 14.7 |

225 | 5.5 | 6.9 | 8.6 | 10.8 | 13.4 | 16.6 |

250 | 6.2 | 7.7 | 9.6 | 11.9 | 14.8 | 18.4 |

280 | 6.9 | 8.6 | 10.7 | 13.4 | 16.6 | 20.6 |

315 | 7.7 | 9.7 | 12.1 | 15 | 18.7 | 23.2 |

355 | 8.7 | 10.9 | 13.6 | 16.9 | 21.1 | 26.1 |

400 | 9.8 | 12.3 | 15.3 | 19.1 | 23.7 | 29.4 |

450 | 11 | 13.8 | 17.2 | 21.5 | 26.7 | 33.1 |

500 | 12.3 | 15.3 | 19.1 | 23.9 | 29.7 | 36.8 |

560 | 13.7 | 17.2 | 21.4 | 26.7 | 一 | 一 |

630 | 15.4 | 19.3 | 24.1 | 30 | 一 | |

No. | item | performance requirements |

1 | standard | GB/T10002.1-2006 |

2 | appearance | the internal and external surfaces of the pipe shallbe smooth and free from obvious scratches,dents,visible impurities and other surface defects affecting the requirements of this section.The end face of the pipe shall be cut flat and perpendicular to the axis. |

3 | specification(OD,EN) | conform tolerance requirements |

4 | density | 1350~1460 |

5 | vicat softening temperatureicat softening temperature | ≥80°C |

6 | longitudinal shrinkage rate % | ≤5% |

7 | dichloromethane impregnation | surface change is not less than 4N |

8 | drop hammer impact test TIR | ≤5% |

9 | hydraulic test | no crack,no leakage |

10 | Joint seal test | no crack,no leakage |

11 | health performance | conform GB/T17219-1998 |

12 | content of vinyl chloride monomer | ≤1.0mg/kg |

PVC-M pipe for water supply

Basic Information:

PVC-M pipe is a new type of pipe with high strength and toughness,which is mainly made of PVC resin powder,with impact modifier added and extruded through advanced processing technology.Product implementation industry standard CJ/T272-2008,excellent performance.The pipeline is mature and widely used abroad.

The addition of impact modifier not only maintains the high strength of PVC-U pipeline,but also increases the ductility of materials,thus making products have good toughness and enhancing the safety and

environmental adaptability of pipelines.The product has the advantages of simple connection of PVC-U pipe, flatness and high impact resistance of PE pipe.It is a pipe with excellent comprehensive performance.

Product Feature:

1,light weight,easy to transport and installation.

Due to the high impact resistance modification of raw materials,the pvc-m pipe wall is thicker and lighter under the same pressure.

2.Good rigidity and toughness.

Compared with ordinary pvc-u pipe of the same specification,the impact resistance is improved significantly, and it can resist point load and uneven settlement of foundation more effectively.

3,health and environmental protection,no pollution,ensure the water quality,no scaling,no breeding bacteria.

4.Simple and reliable connection

5.Lower cost of pipeline operation and maintenance.

6,corrosion resistance,long service life.

Chemical corrosion resistance,can be used in any ordinary pvc-u pipe applications.Under normal service conditions,the service life is more than 50 years.

Product Application:

The products are widely used in municipal water supply and drainage,civil water supply and drainage, industrial water supply,industrial drainage,irrigation and vegetation watering.

Specification:

Outside diameter (mm) | Wallthickness(mm) | |||||

SDR51 | SDR41 | SDR33 | SDR26 | SDR21 | SDR17 | |

PN0.63 | PN0.8 | PN1.0 | PN1.25 | PN1.6 | PN2.0 | |

20 |

|

|

|

| 2 | 2 |

25 |

|

|

|

| 2 | 2 |

32 |

|

|

|

| 2 | 2 |

40 |

|

|

|

| 2 | 2.4 |

50 |

|

|

| 2 | 2.4 | 3 |

63 |

|

| 2 | 2.5 | 3 | 3.8 |

75 |

| 2 | 2.3 | 2.9 | 3.6 | 4.5 |

90 | 2 | 2.2 | 2.8 | 3.5 | 4.3 | 5.4 |

110 | 2.2 | 2.7 | 3.4 | 4.2 | 5.3 | 6.6 |

125 | 2.5 | 3.1 | 3.9 | 4.8 | 6 | 7.4 |

140 | 2.8 | 3.5 | 4.8 | 5.4 | 6.7 | 8.3 |

160 | 3.2 | 4 | 4.9 | 6.2 | 7.7 | 9.5 |

180 | 3.6 | 4.4 | 5.5 | 6.9 | 8.6 | 10.7 |

200 | 3.9 | 4.9 | 6.2 | 7.7 | 9.6 | 11.9 |

225 | 4.4 | 5.5 | 6.9 | 8.6 | 10.8 | 13.4 |

250 | 4.9 | 6.2 | 7.7 | 9.6 | 11.9 | 14.8 |

280 | 5.5 | 6.9 | 8.6 | 10.7 | 13.4 | 16.6 |

315 | 6.2 | 7.7 | 9.7 | 12.1 | 15 | 18.7 |

355 | 7 | 8.7 | 10.9 | 13.6 | 16.9 | 21.1 |

400 | 7.9 | 9.8 | 12.3 | 15.3 | 19.1 | 23.7 |

450 | 8.8 | 11 | 13.8 | 17.2 | 21.5 |

|

500 | 9.8 | 12.3 | 15.3 | 19.1 | 23.9 |

|

560 | 11 | 13.7 | 17.2 | 21.4 | 26.7 |

|

630 | 12.3 | 15.4 | 19.3 | 24.1 |

| |

Performance comparison

item | PVC-M pipe | PVC-U pipe | HDPE pipe |

pipe thickness | Very thin | thin | thick |

bending property | Allow some degree of change shape | Hard,not bent | Flexible well |

glancing flatness | Good glancing flatness flatness, not easy to deform | Good glancing flatness flatness, not easy to deform | Low degree of steel, small pipe diameter poor flatness,bending easy to change shape |

impact-resistan ce strength | Restitution within a period of timeafter receiving external impact | Poor toughness, vulnerable to external impact brittle crack | Good toughness,by the external impact can be quickly restored to the original state |

Install connection | Adhesive bond or elastic seal ring connection,simple operation, short construction period | Adhesive bond or elastic seal ring connection, simple operation, short construction period | Hot melt or electro -melt connection. Relatively high cost and long construction time |

price | lower | low | high |

Performance indicators

Item | Index | |

density,kg/m² | 1350-1460 | |

vicat softening temperature,℃ | ≥80℃ | |

longitudinal reversion,% | ≤5% | |

dichloromethane impregnating experiments,15℃15min | surface change is not less than4N | |

drop hammer impact test(0℃)TIR,% | ≤5% | |

hydraulic test | dn<63mm 20℃ 36Mpa 1h | |

dn<63mm 20℃38Mpa 1h | No crack,no leakage | |

60℃ 10Mpa 1000h | ||

system applicability experiment | connection tightness test | No crack,no leakage |

external pressure test | No crack,no leakage | |

deflection Angle test | No crack,no leakage | |

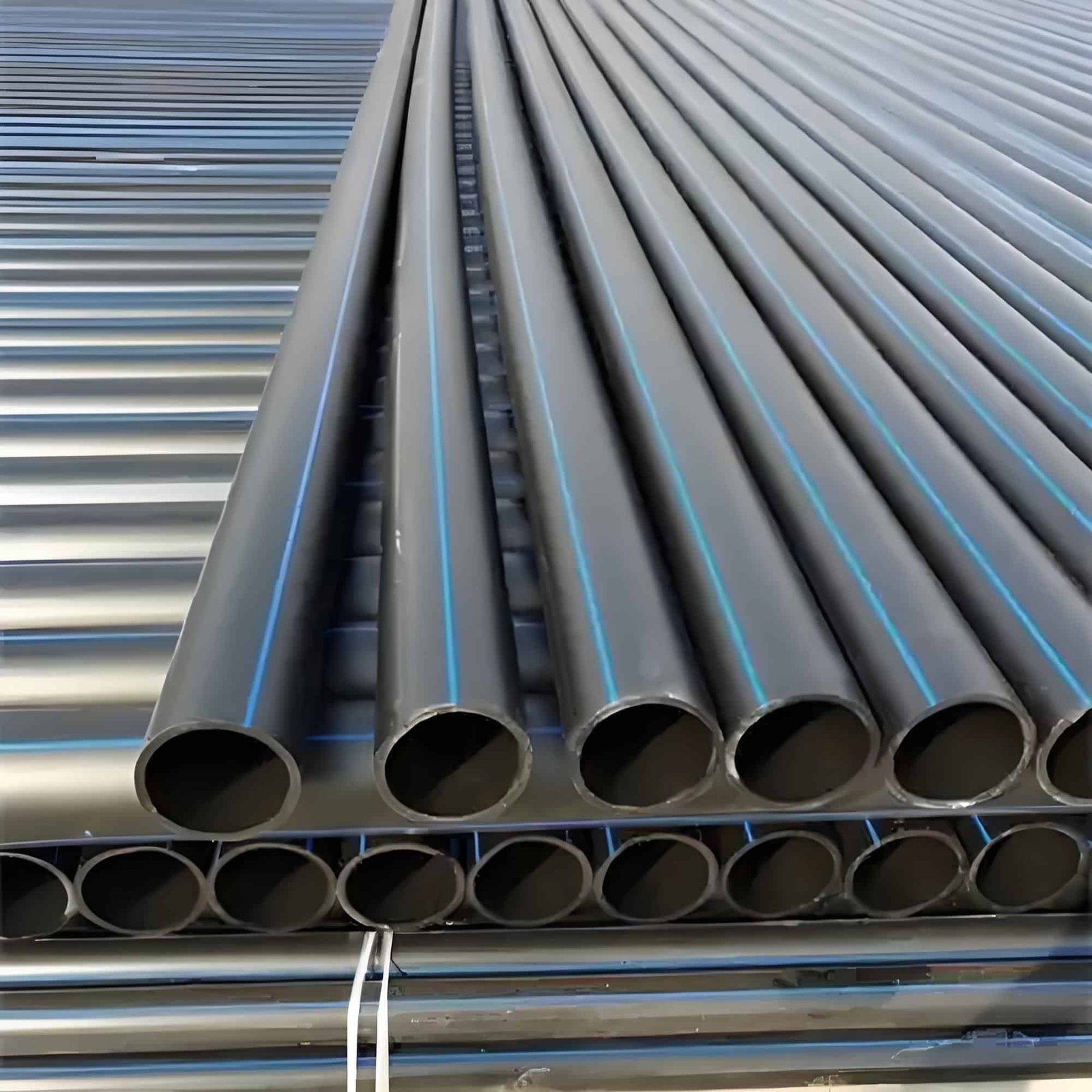

HDPE pipe for water supply

Product introduce:

HDPE pipe supply China’s municipal pipe market,plastic pipe is steadily developing,PE pipe,pp-r pipe, UPVC pipe have a place,among which PE pipe strong development momentum is the most eye-catching.PE pipe is widely used in many fields.Among them,water supply pipe and gas pipe are its two largest application markets.

PE pipe for water supply is traditional steel pipe,UPVC drinking water pipe replacement product.

Product Feature:

1.high strength,resistance to environmental stress cracking performance,good creep resistance.

2.toughness,flexibility,and uneven on the basis of the ability to adapt to dislocation,can withstand earthquakes and typhoons and other harsh environments.

3.has good weather resistance (including anti-ultraviolet properties)and long-term thermal stability.

4.corrosion-resistant,do not need to do anti-corrosion treatment,long service life.

5.the inner wall is smooth,the water current resistance is small,the circulation ability is big,saves the construction cost.

6.wear resistance.

7.low-temperature impact resistance,and can be-20-40℃ temperature range of safe use,winter construction is not affected.

8.Fused (or hot melt)connection is convenient and reliable,construction and maintenance of convenience (during which can not stop the water).

9.fully suitable for traditional excavation construction methods and pipe jacking,directional drilling,liner,pipe cracking,submerged underwater and other new trenchless technology.

10.polyethylene raw materials contain only carbon,hydrogen two elements,harmless to the human body.

11.The use of advanced nano-antibacterial technology,effectively inhibit the growth of algae,bacteria and fungi,is green,healthy,environmentally friendly drinking water pipeline.

Product Application:

1.urban water network system.

2.urban and rural drinking water pipeline.

3.liquid transport pipeline for chemical,chemical fiber,food,forestry,printing and dyeing,pharmaceutical,light industry,paper making,metallurgy and other industries.

4.agricultural irrigation pipes.

5.post and telecommunication lines,power wire protection casing.

6.mine mortar pipeline.

Pipe connection:

1.electric hot melt connection:use special electric hot melt welding machine to connect straight pipe with straight pipe,straight pipe with pipe fitting.Generally used for 160mm pipes.

2.Hot melt butt connection:use a special butt welding pipe connected,generally used for more than 160mm pipe.

3.steel-plastic connection:flange,screw thread and other methods can be used for connection.

4.appropriate tools should also be prepared to facilitate construction and ensure construction quality

HDPE water pipe advantages

1.High strength,excellent environmental stress cracking resistance,good creep resistance;

2.Good toughness and flexibility,strong adaptability to uneven foundation and dislocation,and able to resist the harsh environment such as earthquake and typhoon;

3.Good weather resistance (including uv resistance)and long-term thermal stability;

4.Corrosion resistance,no need for corrosion treatment,long service life;

5.Smooth inner wall,small flow resistance,large circulation capacity,saving construction cost;

6.Good wear resistance and wear resistance;

7.Good low-temperature impact resistance,safe to use in the temperature range of-20~40℃,not affected by winter construction;

HDPE 100 water pipe specificaiton:

Outside Diameter (mm) |

Wall Thickness(mm) | ||||

SDR26(PN0.6) | SDR21(PNO.8) | SDR17(PN1.0) | SDR13.6(PN1.25) | SDR11(PN1.6) | |

20 |

|

|

|

| 1.9 |

25 |

|

|

| 1.9 | 2.3 |

32 |

|

|

| 2.4 | 3 |

40 |

|

| 2.4 | 2.9 | 3.7 |

50 |

|

| 3 | 3.7 | 4.6 |

63 |

| 3 | 3.8 | 4.7 | 5.8 |

75 |

| 3.6 | 4.5 | 5.6 | 6.8 |

90 |

| 4.3 | 5.4 | 6.7 | 8.2 |

110 | 4.2 | 5.3 | 6.6 | 8.1 | 10 |

125 | 4.8 | 6 | 7.4 | 9.2 | 11.4 |

160 | 6.2 | 7.7 | 9.5 | 11.8 | 14.6 |

200 | 7.7 | 9.6 | 11.9 | 14.7 | 18.2 |

225 | 8.6 | 10.8 | 13.4 | 16.6 | 20.5 |

250 | 9.6 | 11.9 | 14.8 | 18.4 | 22.7 |

315 | 12.1 | 15 | 18.7 | 23.2 | 28.6 |

355 | 13.6 | 16.9 | 21.1 | 26.1 | 32.2 |

400 | 15.3 | 19.1 | 23.7 | 29.4 | 36.3 |

450 | 17.2 | 21.5 | 26.7 | 33.1 | 40.9 |

500 | 19.1 | 23.9 | 29.7 | 36.8 | 45.4 |

560 | 21.4 | 26.7 | 33.2 | 41.2 | 50.8 |

630 | 24.1 | 30 | 37.4 | 46.3 | 57.2 |

710 | 27.2 | 33.9 | 42.1 | 52.2 |

|

800 | 30.6 | 38.1 | 47.4 | 58.8 |

|

900 | 34.4 | 42.9 | 53.3 |

|

|

1000 | 38.2 | 47.7 | 59.3 |

| |

HDPE 100 pipe performance:

item | performance requirements | |

20℃ Hydrostatic strength(hoop stress12.4MPa,100h) | No cracking,no leakage | |

80℃ Hydrostatic strength(hoop stress 5.5MPa,165h) | No cracking,no leakage | |

80℃ Hydrostatic strength(hoop stress 5.0MPa,1000h) | No cracking,no leakage | |

Elongation at break,% | ≥350 | |

Longitudinal shrinkage(110℃),% | ≤3 | |

Oxidation induction time(200℃),min | ≥20 | |

Weather resistance 1) (pipe accumulation Aging≥3.5GJ/m2 was accepted After the energy) | 80℃Hydrostatic strength(hoop stress 4.6MPa,165h) | |

No cracking,no leakage | ||

Elongation at break,% | ≥350 | |

PP-R pipe for cold and hot water supply

Basic Information:

PP-R environmental protection hot and cold water pipe series products are produced in accordance with the high standards and strict requirements of ISO9001 quality system,and the products fully comply with GB/T18742.1,GB/T18742.2,GB/T18742.3,GB/T17219-1998 health standards and the relevant health and safety evaluation regulations of the ministry of health of the People’s Republic of China.PP-R drinking water pipe is a new kind of product is generally used to developed countries in the world today,it is in the hot and cold water transportation engineering using homogeneous welding technology,its comprehensive performance is much better than other similar products and economic indicators,especially its excellent health performance, can achieve the whole process from production to use waste recycling high health,environmental protection requirements.

Outside diameter (mm) | Wall Thickness(mm) | |||

PPR cold water pipe | PPR cold and hot water pipe | |||

1.25mpa | 1.6mpa | 2.0mpa | 2.5mpa | |

16 | 一 | 2 | 2.2 | 2.7 |

20 | 2 | 2.3 | 2.8 | 3.4 |

25 | 2.3 | 2.8 | 3.5 | 4.2 |

32 | 2.9 | 3.6 | 4.4 | 5.4 |

40 | 3.7 | 4.5 | 5.5 | 6.7 |

50 | 4.6 | 5.6 | 6.9 | 8.3 |

63 | 5.8 | 7.1 | 8.6 | 10.5 |

75 | 6.8 | 8.4 | 10.3 | 12.5 |

90 | 8.2 | 10.1 | 12.3 | 15 |

110 | 10 | 12.3 | 15.1 | 18.3 |

160 | 14.6 | 17.9 | 21.9 | 26.6 |

Product Feature:

1.Health,non-toxic,no rust,never scale;

2.High temperature resistant(top conveying water temperature of 95℃),high pressure resistance (resistance to pressure test strength up to more than 5 mpa);

3.Hot-melt connection is adopted to integrate the homogeneous melting of pipes and fittings,which is safe and reliable and willnever leak;

4.Low thermal conductivity,0.21w/mk of pp-r pipe (only 1/200th of metal pipe),good thermal insulation performance;

5.Light weight,easy handling,low construction intensity;

6.Smooth inner wall,small pressure loss and fast water flow;

7.The pipe conveying noise is low,and the noise decreases by 40%(compared with galvanized pipe);

8.The product is soft in color,beautiful in appearance,and can be installed in both light and dark;

9.Good chemical corrosion resistance;

10.Easy and quick installation,low construction cost;

11.Long service life,which can be more than 50 years under normal conditions.

Product Application:

1.The cold and hot water system of the building,including the central heating system;

2.The heating system in the building,including the main pipe of the floor and wall panel radiant heating system;

3.Potable pure water supply system and food industry pipeline system;

4.Central (centralized)air-conditioning system and traditional heating system;

5.Irrigation system for public places,gardens and greenhouses;

6.Industrial piping system for conveying or discharging chemical media.

HDPE double-wall bellows

Product introduce:

HDPE double wallcorrugated pipe is a new type of pipe with annular outer wall and smooth inner wall.It was first developed in Germany in the early 1980s.After more than ten years of development and improvement,has developed from a single variety to a complete product series.At present in the production process and the use of technology has been very mature.Because of its excellent performance and relative economic cost,it has been widely used in developed countries such as Europe and America.In China,HDPE double wall bellows are in the phase of rising trend of promotion and application,all the technical indicators are up to the use standard.The inner walls of double-wall corrugated tubes are usually blue and black,and some brands use yellow.

Product Feature:

1.Unique structure,high strength,compression and impact resistance.

2,smooth inner wall,friction,large flow.

3,convenient connection,joint sealing,no leakage.

4.Light weight,quick construction and low cost.

5,buried life of more than 50 years.

6.Polyethylene is a hydrocarbon polymer with non-polar molecules and is resistant to acid and alkali corrosion.

7.The raw material is green and environment-friendly material,non-toxic,non-corrosive,non-scale,and recyclable.,suitable temperature range wide,8-10℃environment pipeline rupture,the medium of the highest temperature of 40℃ .

8.The comprehensive engineering cost is basicallythe same as that of concrete,and the operation cost is low.

9.good soil conditions do not need a foundation.

Product Application:

1.Drainage and ventilation pipes of mines and buildings;

2.Municipal engineering,underground drainage and sewage pipes of residential areas;

3.Irigation,water transmission and drainage;

4.Sewage treatment plant and waste disposal plant drainage pipes;

5.Chemical ventilation pipes and conveying pipes used for fluid in chemical industry and mine;

6.Overall machining of pipeline inspection Wells;

7.Embedded pipeline of expressway;

8.High voltage cable,post and telecommunication cable protection sleeve,etc

Performance indicators:

Item | performance index | |

ring-stiffness | SN4 | ≥4KN/M² |

SN8 | ≥8KN/M² | |

impact strength | TIR≤10% | |

Flexible | The sample is smooth,no reverse bending, no cracking,and no separation of the two walls | |

oven test | No bubbles,no layering,no cracking | |

creep rate | ≤4 | |

Specification:

Nominal diameter DN/ID(mm) | Minimum mean inner diameter (mm) | Minimum laminated wallthickness (mm) | Minimum inner wall thickness (mm) |

bonding length (mm) |

200 | 195 | 1.5 | 1.1 | 54 |

300 | 294 | 2 | 1.7 | 64 |

400 | 392 | 2.5 | 2.3 | 74 |

500 | 490 | 3 | 3 | 85 |

600 | 588 | 3.5 | 3.5 | 96 |

800 | 785 | 4.5 | 4.5 | 118 |

HDPE steel belt reinforced spiral bellows

Product introduce:

HDPE steel belt reinforced spiral bellows are made of HDPE as the matrix,and the steel belt coated with adhesive resin is formed into waveform as the main supporting structure,and the double wall spiral bellows are wound and compounded with polyethylene material as a whole.Steel belt reinforced polyethylene(PE)spiral corrugated pipe of high rigidity,high strength steel and plastic,such as corrosion resistance,wear resistance and flexibility is better,not only can make the pipe to SN8,SN12.5,SN16 three ring stiffness,and solve the problem of the corrosion of steel,makes up for the large diameter of the plastic underground drainpipe normally only reached the ring stiffness SN8 weakness.

Material | Polyethylene,steel belt |

Working Temperature | -30°C-+100°C,short time to+120°C |

Structure | internal and external are wavy |

Color | Black,other colors can be customized |

Features | Good flexibility,twist resistance,bending resistance,abrasion acid,oil,coolant, |

etc.Shiny surfact can withstand heavy loads | |

Carring Capacity | can withstand the weight of foot,no broken,deformed,can be quickly restored |

and without any damage itself. | |

Application Area | Applicable to machine tools,power equipment,food machinery,automative |

instrument,motor industry etc. | |

Usage | put wires and cables into the flexible pipe and match with quick connector RQG |

seriers |

Performance index:

ltem | index | |

Ring stifness(kN/m2) | SN8 | ≥8 |

SN10 | ≥10 | |

SN12.5 | ≥12.5 | |

SN16 | ≥16 | |

Impact performance | TIR≤10% | |

Ring flexibility | No cracks,no separation on both walls | |

Oven test | No delamination,no cracking | |

Tensile strength | ≥1460N | |

Product Application:

1.Municipal engineering rainwater and sewage discharge

2.Industrial wastewater discharge and community drainage project

3.Salt transport and fishery water transport

4.Agriculture,forestry,drainage and irigation

5.Water conservancy projects

6.Ventilation system

7.Cable and wire sheath

Product Feature:

1.The pipeline material with strong corrosion resistance is PE,which will not be corroded by acid,alkali and oil.

2.The pipeline with strong resistance to external forces has the shape of spiral structure and flexibility.When it is subjected to external impact,it has strong resilience.

3.strong aging resistance pipeline substrate characteristics at 20 degrees can be effectively used for more than50 years,has a strong aging resistance.

4.strong cold resistance in the environment of minus 60 degrees,pipe will not be frozen broken water.

5.The light weight is only 1/8 of the concrete pipe of the same specification and 2/3 of the traditional wound plastic structural pipe,which is convenient for transportation and construction and does not require large construction equipment,thus reducing the installation cost.

6.Low construction cost,light weight,convenient connection,and low requirements for excavation projects.It can save project time and costs in urban drainage project construction.

7.easy to connect the connection of various ways,simple,reliable.The site can be easily constructed.

8.superior abrasion resistance pipeline friction coefficient low,small resistance,transmission medium,drainage, sewage speed.

9.good environmental performance Pe itself is non-toxic renewable material,environmental health.

10.High ring stiffness can reach SN12.5 and SN16

PVC-U drainage pipe

Product introduce:

PVC-U drainage pipe drain is sanitary grade polyvinyl chloride(PVC)resin as the main raw material,adding an appropriate amount of stabilizer,lubricant,filler,toner and other plastic extruder extrusion molding and injection molding machine,through cooling,curing,shaping,inspection,packaging and other procedures to complete the production of pipe,pipe fittings

Specification:

outside diamter (mm) | mean outside diameter deviation (mm) | Wall thickness and deviation (mm) | Length(m) |

40 | 0.3 | 2.0+0.4 | 4or6 |

50 | 0.3 | 2.0+0.4 | 4or6 |

75 | 0.3 | 2.3+0.4 | 4or6 |

110 | 0.4 | 3.2+0.6 | 4or6 |

160 | 0.5 | 4.0+0.6 | 4or6 |

200 | 0.6 | 4.9+0.6 | 4or6 |

250 | 0.6 | 6.2+0.6 | 4or6 |

315 | 0.7 | 7.8+0.6 | 4or6 |

Performance index:

ltem | Index |

density(kg/m²) | 1350-1550 |

Vicat Softening Temperature | ≥79℃ |

(VST) | ≤5% |

Longitudinal shrinkage rate | Surface change |

Dichloromethane immersion test | is not worse than 4L |

tensile yield strength | ≥40Mpa |

dart drop impact test(TIR) | ≤10% |

Product Feature:

- 1.Light weight,convenient handling and handling:

PVC pipe material is very light,handling,construction is convenient,can save labor.

- 2.Excellent chemical resistance

PVC pipe has excellent acid,alkali and corrosion resistance,suitable for chemical industry.

- 3.Low fluid resistance

The wall surface of PVC pipe is smooth and the resistance to fluid is small.Its roughness coefficient is only 0.009,lower than that of other pipes.At the same flow rate,the pipe diameter can be reduced.

- 4.High mechanical strength

PVC pipe has good water pressure resistance,external pressure resistance,impact resistance,etc.

- 5.Good electrical insulation

PVC pipe is rich in superior electrical insulation,suitable for wire,cable conduit,and building wire piping.

- 6.It does not affect water quality

PVC pipe proved by dissolution test does not affect the water quality,for the current tap water with the best pipe.

- 7.Simple construction

The connection between PVC pipes is quick and easy,so the construction cost is low

Product Application:

The products are widely used in municipal water supply and drainage,civil water supply and drainage, industrial water supply and drainage,irrigation and vegetation watering,etc.

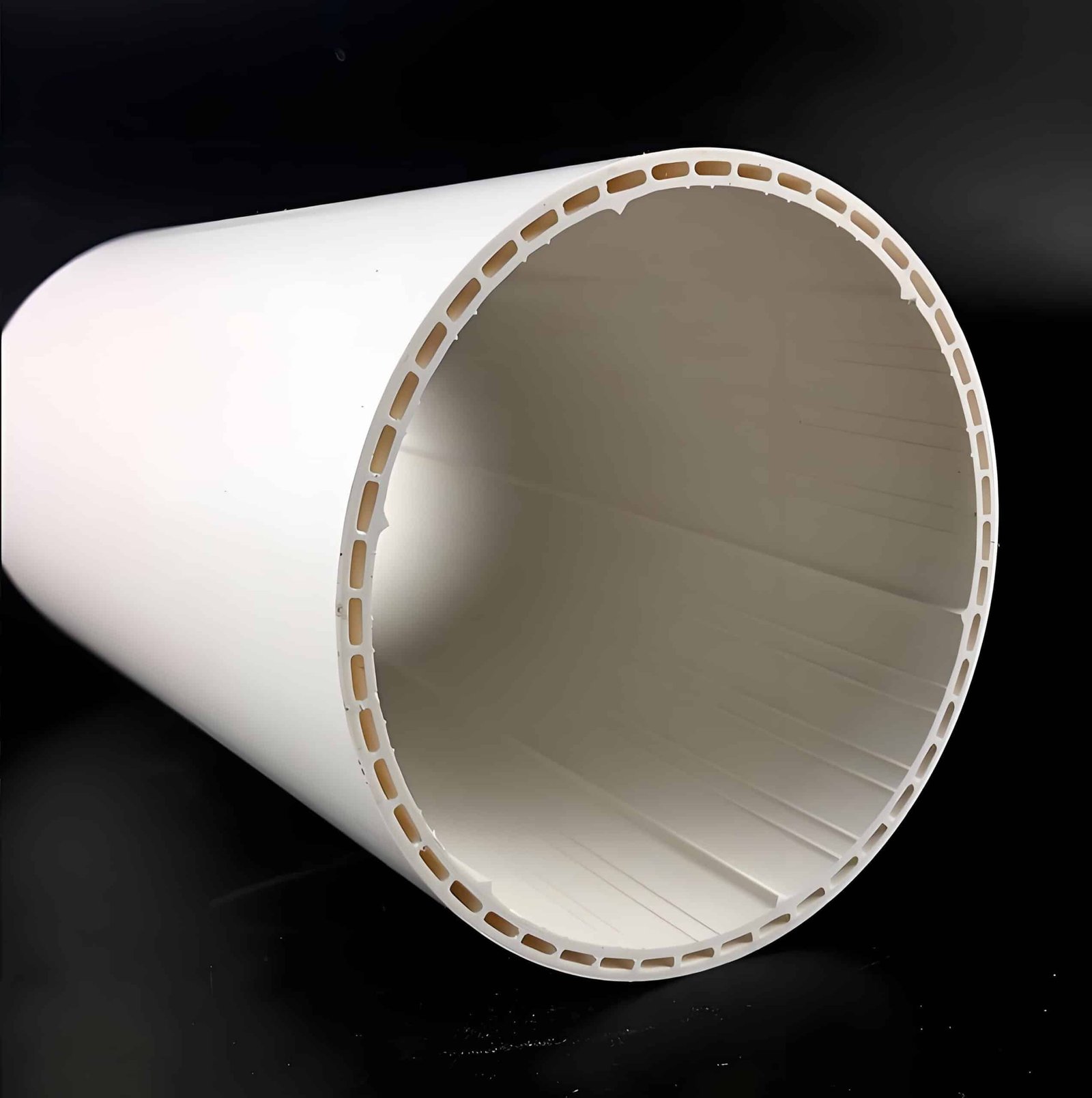

PVC-U double - walled hollow spiral silencing pipe

Product introduce:

PVC-U double-walled hollow spiral silencing pipe is PVC-U as the main raw material,add the necessary additives,the use of advanced production equipment and technology,the extrusion forming of tube wall double layer structure and several triangular spiral rib,the noise of the drainage of hollow wall pipe.The protruding triangular spiral rib in the tube wall has the same performance as the real spiral tube.Because the tube wall adopts a double-layer structure with a hollow layer in the middle,it can effectively isolate the noise generated by the water flow in the tube from the external transmission,and the noise elimination effect is more obvious

Specification:

loutside diameter (De mm) |

Thickness/mm |

number of Screw arris |

number of blank |

50 |

|

|

|

75 | 5 | 6 | 22 |

110 | 6 | 6 | 24 |

160 | 7 | 6 | 32 |

Performance index:

ltem | Performance index |

vicat softening temperature | ≥79℃ |

tensile yield strength | ≥28Mpa |

ring-stiffness | ≥8.0KN/m² |

flattening test | No cracking |

dart drop impact test | >90% |

longitudinal reversion | <9% |

Product Feature:

1.Six streamlined spiral internal ribs enable water to swirl down against the inner wall of the pipe,greatly reducing the noise of the pipe system.

2.The outer wall of the pipe is a hollow and porous structure,in which the empty layer can further block the noise generated during drainage to enhance the sound elimination effect of the pipe.

3.Under the guidance of the spiral internal bar of the pipe,the water flow falls spirally along the wall of the pipe, and the unblocked air column is formed in the center of the drainage riser,which has a strong ventilation ability.No additional exhaust pipe is needed to reduce the project cost.

4.The spiral muffler pipe fitting with unique design makes the water flow into the riser along the tangential

direction to reduce the collision of water flow and thus reduce the noise.The pipe fitting can also play the role of expansion joint to compensate the change of pipe length caused by thermal expansion and cold contraction.

5.The hollow structure of the outer wall of the pipe can play a good insulation effect and prevent the condensation phenomenon on the outer wall of the pipe.

Product Application:

It is suitable for the indoor muffler drainage system of high class office,conference hall,hotel,guesthouse, apartment,villa and high grade residential area.

PVC-U power cable protection pipe

- Material Characteristics

- Heat Resistance

- Insulation Performance

- Compression Resistance

- High Impact Resistance

- Good Flame Retardant Performance

- Installation Performance

- Long Service Life

Performance index:

ltem | technical index |

appearance | pipe wallno bubble,no crack decomposition |

color line,no impurities | |

color | Colour and lustre is uniform |

Drop hammer impact test(TIR20℃) | pass 9/10 |

flattening test | no crack |

ring-stiffness(KN/m²) | ≥6.3 |

Application:

Telecom,cable sleeve;Highway communication pipeline defense communication,railway communication pipeline street lamp and various communication light (electrical)bushing

PVC-C power cable protection pipe

Performance index:

No. | ltem | Performance indicators |

1 | executive standard | QB/T 2479-2000 |

2 |

appearance | The inner and outer walls of the products should be smooth and even,without bubbles, cracks and obvious marks,depressions and discoloration lines.The color is orange red. |

3 | vicat softening temperature ℃ | ≥93 |

4 | Volume resistivity(Ω ·cm) | ≥1.0*10^13 |

5 | Hot compression force of ring plate (KN)(EN≤7.0mm) |

≥0.70 |

6 | Hot compression force of ring plate (KN)(EN≥8.5mm) |

≥1.26 |

7 | flame retardation | grade FV-0 |

8 | coefficient of friction | ≤0.35 |

9 | tortuosity(%) | ≤1.0 |

10 | drop hammer impact test | pass 9/10 |

11 | density(kg/m3) | 1350~1500 |

12 | oxygen index% | ≥40 |

13 | through overload test | deformation of pipe is less than 2.5% |

14 | longitudinal shrinkage rate≤ | 5% |

- Widely used in urban power grid construction and transformation.

- Urban reconstruction projects.

- Civil aviation airport construction.

- Campus engineering.

- Community project construction.

- Traffic, road and bridge construction, as well as urban streetlight cable laying, where it plays a guiding and protective role.

HDPE power cable protection pipe

- Excellent Physical Properties: Produced with high-quality polyethylene, it has good rigidity, strength, and flexibility, which is beneficial for pipe installation.

- Corrosion Resistance and Long Service Life: In coastal areas with a high water table and high soil moisture, metal or other pipelines must be anti-corrosive and generally only last for 30 years. However, PE pipes can withstand various chemical media and are not affected by soil corrosion.

- Good Toughness and Deflection: PE pipe is a kind of high-toughness pipe with a breaking elongation of more than 500%. It has a strong ability to adapt to uneven ground settlement and foundation dislocation, good shock resistance, and small-diameter pipes can be bent arbitrarily.

- Smooth Tube Wall: With a small friction coefficient, it is easy to install cables, and the construction efficiency is high.

- Good Electrical Insulation Performance: It has a long service life (the buried pipe life is more than 50 years), is durable, and ensures safe and reliable line operation.

- Light Weight: It is convenient for maintenance, transportation, and operation.

- Coil Pipe Form for Small-diameter Pipes: Small-diameter pipes can be in the form of coil pipes, with long pipe sections, few joints, and easy installation.

- Color-coded: Pipes can be made into various colors for easy distinction.

- Excellent Low-temperature Impact Resistance: The low-temperature embrittlement temperature of PE is very low, and it can be used safely within the temperature range of -20℃ to 40℃. During winter construction, due to the good impact resistance of the material, the pipes will not become brittle.

- Good Abrasion Resistance: Compared with other metal pipes, the abrasion resistance of PE pipes is four times that of metal pipes.

- Diverse Construction Methods: In addition to the traditional excavation method, PE pipes can also be constructed using a variety of new trenchless technologies, such as pipe jacking, lining, pipe cracking, etc., making it the only choice for sites where excavation is not allowed.

MPP power cable protection pipe

Commonly used specifications:

No. | Nominal diameter (mm) | wall thickness (mm) |

No. | Nominal diameter (mm) | wall thickness (mm) |

1 | 110 | 5 | 14 | 180 | 8 |

2 | 110 | 6 | 15 | 180 | 10 |

3 | 110 | 8 | 16 | 180 | 12 |

4 | 125 | 8 | 17 | 200 | 10 |

5 | 125 | 9 | 18 | 200 | 12 |

6 | 125 | 10 | 19 | 200 | 13 |

7 | 160 | 5 | 20 | 225 | 12 |

8 | 160 | 8 | 21 | 225 | 13 |

9 | 160 | 9 | 22 | 225 | 15 |

10 | 160 | 10 | 23 | 250 | 17 |

11 | 160 | 12 | 24 | 280 | 18 |

12 | 166 | 8 | 25 | 315 | 25 |

13 | 170 | 10 |

|

|

|

Performance indicators:

Item | Index | Test method |

density g/cm3 | 0.91-0.95 | GB/033-86 |

Sliding friction series | <0.35 | GB/T3960-89 |

tensile strength(23±2)℃ | ≥22.0 | GB/T1040-92 |

(70±2)℃ Mpa | ≥16.5 | |

hot melt joint tensile strength Mpa | ≥21.6 | GB/T3960-92 |

flexural strength (23±2)℃ Mpa | ≥34.0 | GB/T9341-2000 |

flexural modulus Mpa | 900-1200 | GB/T9341-2000 |

flattering test (D/2,-5℃) | no cracking | GB9647-88 |

vicat softening temperature (10N.50℃/h)℃ |

≥120 |

GB/T1633-2000 |

drop-hammer impact test (-5℃)D>160mm 10kg*2m |

9/10 no cracking |

GB/T6112-1985 |

D≤160mm 6kg*2m | ||

D≤125mm 5kg*2m |

- MPP pipe has excellent electrical insulation.

- MPP pipe has high thermal deformation temperature and low temperature impact performance.

- The tensile and compressive properties of MPP tube are higher than HDPE.

- MPP pipe is light, has a smooth surface, offers small friction force, and can be hot welded and butt – jointed.

- MPP pipe can be used for a long time at a temperature range of 5~70℃.

PVC-U electrical conduit pipe

Specification:

Outside diameter | light-type | middle-type | heavy-type |

(mm) | inner diameter(mm) | inner diameter(mm) | inner diameter(mm) |

16 | 13.7 | 13 | 12.2 |

20 | 17.4 | 16.9 | 15.8 |

25 | 22.1 | 21.4 | 20.6 |

32 | 28.6 | 27.8 | 26.6 |

40 | 35.8 | 35.4 | 34.4 |

Note:Other specifications can be negotiated | |||

performance index:

lItem | Index |

density(gcm²) | 0.91-0.96 |

coefficient of sliding friction | <0.35 |

Veka softening temperature℃ | ≥80 |

tensile strength(Mpa) | ≥24.0 |

hot melt joint tensile strength(Mpa) | ≥21.6 |

flexural strength(Mpa) | ≥37.0 |

flexural modulus(Mpa) | 900-1500 |

flattering test(1/2) | no cracking |

dart drop impact test | 9/10 no cracking |

Heat compression force in exchange(KN) | ≥1.8 |

Product Features

- The inner and outer walls of the pipe fittings are smooth and the friction coefficient is small.

- High compression resistance.

- Good impact resistance and heat resistance.

- Moisture resistance, acid and alkali resistance.

- Flame retardant.

- Insulation.

- Resistance to insects.

- Convenient construction.

PVC-U low pressure irrigation pipe

- Good Mechanical Performance: PVC-U agricultural irrigation pipe has high rigidity and strong resistance to external forces. When used for buried water transmission, it is not easily damaged by external forces.

- Smooth Inner Wall: The inner wall of the PVC-U agricultural irrigation pipe is smooth, resulting in low fluid resistance and no rust formation. It has lenient water quality requirements, with no accumulation inside and is not prone to blockage.

- Small Linear Expansion Coefficient: The linear expansion coefficient of the PVC-U pipe is small. Even when the environmental temperature changes significantly, the pipe will not undergo obvious deformation that could affect the irrigation effect.

- Excellent Anti-aging Performance: Antioxidants and light stabilizers are added to the formula of the PVC-U agricultural irrigation pipe, endowing it with excellent anti-aging properties. This ensures its durability whether under long-term illumination or buried underground.

- Complete Set of Pipes and Fittings: The pipes and fittings have stable sizes, avoiding installation difficulties or water seepage caused by large tolerance in fittings.

- Stable and Sanitary Performance: The pipe has stable performance and good sanitary properties. It does not affect water quality, and is non-toxic and pollution-free, posing no harm to crops.

- Simple Connection Modes: The connection between PVC-U pipes and fittings for irrigation is simple, mainly including bonding and thread bonding, with bonding being the commonly used method. When the adhesion is properly done, the connection of the PVC-U pipe is stronger than the pipe body itself.

- Light Weight: It is light in weight, making transportation, installation, and use convenient.

Specification:

nominal diameter (mm) | outside diameter (mm) |

tolerance(mm) |

50 | 50 | ±0.3 |

75 | 75 | ±0.4 |

100 | 100 | ±0.4 |

125 | 125 | ±0.5 |

160 | 160 | ±0.5 |

200 | 200 | ±0.6 |

250 | 250 | ±0.8 |

315 | 315 | ±0.9 |

Note:wall thickness can be customized | ||

Performance index:

Item | Index |

density(kg/m²) | 1400-1600 |

longitudinal shrinkage | ≤5% |

tensile yield pressure | ≥40MPa |

hydraulic test | No crack,no leakage |

dart drop impact test | No crack |

stiffness(5%) | ≥0.04MPa |

flattering test(The pressure to 50%) | No crack |

Application:

Used in agricultural irrigation widely

PE low pressure irrigation pipe

- Good abrasion resistance, non-toxic, UV resistant and flexible.

- With anti-aging agent added, it has a long service life and excellent corrosion resistance.

- It can not only replace the wool canal to reduce the loss of water transmission in the field, but also strictly control and regulate the irrigation water consumption in the field.

- Integrates the field water delivery and field irrigation control system.

- Low energy consumption, low input, low irrigation cost, high standard water saving and high efficiency.

- Combines pipeline water transmission with field water-saving technology.

Performance index:

Item | Index |

elongation at break,% | ≥350 |

longitudinal reversion, (110℃),% |

≤3 |

resistant to environmental stress cracking | Not more than 10% the number of unqualified bending |

static oxidation induction time (200℃)min |

≥20 |

hydrostatic test(20℃) | No cracking,no leakage |

The annular stress of PE63 grade pipe is 8.0Mpa(100h)and that of PE80 grade pipe is 9.0Mpa(100h) | |

Application:

1.Agricultural irrigation

2.Landscape irrigation project

HDPE gas pipe

Specification:

HDPE80/ HDPE100

gas

pipe

series | nominal | normal wall thickness(mm) | |

outside diameter(mm) | SDR11 | SDR17 | |

20 | 3.0 | 2.3 | |

25 | 3.0 | 2.3 | |

32 | 3.0 | 2.3 | |

40 | 3.7 | 2.3 | |

50 | 4.6 | 2.9 | |

63 | 5.8 | 3.6 | |

75 | 6.8 | 4.3 | |

90 | 8.2 | 5.2 | |

110 | 10.0 | 6.3 | |

125 | 11.4 | 7.1 | |

160 | 14.6 | 9.1 | |

180 | 16.4 | 10.3 | |

200 | 18.2 | 11.4 | |

225 | 20.5 | 12.8 | |

250 | 22.7 | 14.2 | |

280 | 25.4 | 15.9 | |

315 | 28.6 | 17.9 | |

355 | 32.2 | 20.2 | |

400 | 36.4 | 22.8 | |

Performance index:

ltem | Index | |

Static night pressure (HS),h | 20℃(环应力) PE809.0Mpa PE10012.4Mpa |

breakdown time≥100 |

80℃(环应力) PE804.5Mpa PE1005.4Mpa |

breakdown time≥165 | |

80℃(环应力) PE804.0Mpa PE1005.0Mpa |

breakdown time≥1000 | |

elongation at break | ≥350% | |

Black carbon content(mass fraction), (black mix only) |

2.0-2.5% | |

Oxidation induction time,min | 200℃ | >20 |

Mass flow rate (MFR),g/10min | 195℃,5kg | Changes of MFR before and after processing<20% |

longitudinal reversion | 110℃ | ≤3 |

Gas component,H | 80℃,2Mpa(Ring stress) | ≥20 |

- Reliable connection

- Good low-temperature impact resistance: It can be used safely within the temperature range of -60℃ to 60℃. During winter construction, no brittle pipe cracks will occur.

- Good stress cracking resistance: HDPE has low notch sensitivity, high shear strength, and excellent scratch resistance, with prominent environmental stress cracking resistance.

- Good chemical corrosion resistance

- Aging resistance and long service life: It can be stored outdoors or used for 50 years.

- Excellent abrasion resistance

- Good flexibility

- Small flow resistance

- Convenient handling

- Ability to use a variety of new construction methods, with wider application fields

- Hot melt connection

- Electric melt connection

- Steel-plastic transition joint connection or flange connection and other methods

- For pipes and fittings with a diameter ≥ 90mm, hot melt connection shall be adopted.

- For pipes and fittings with a diameter < 90mm, electric welding shall be adopted.

- Steel-plastic transition joints or flanges shall be used to connect pipes with metal and other materials – made pipe accessories.